"Mother's Day",

"Wardrobe Refashion",

"clothes",

"handmade",

"mom",

"wedding dress"

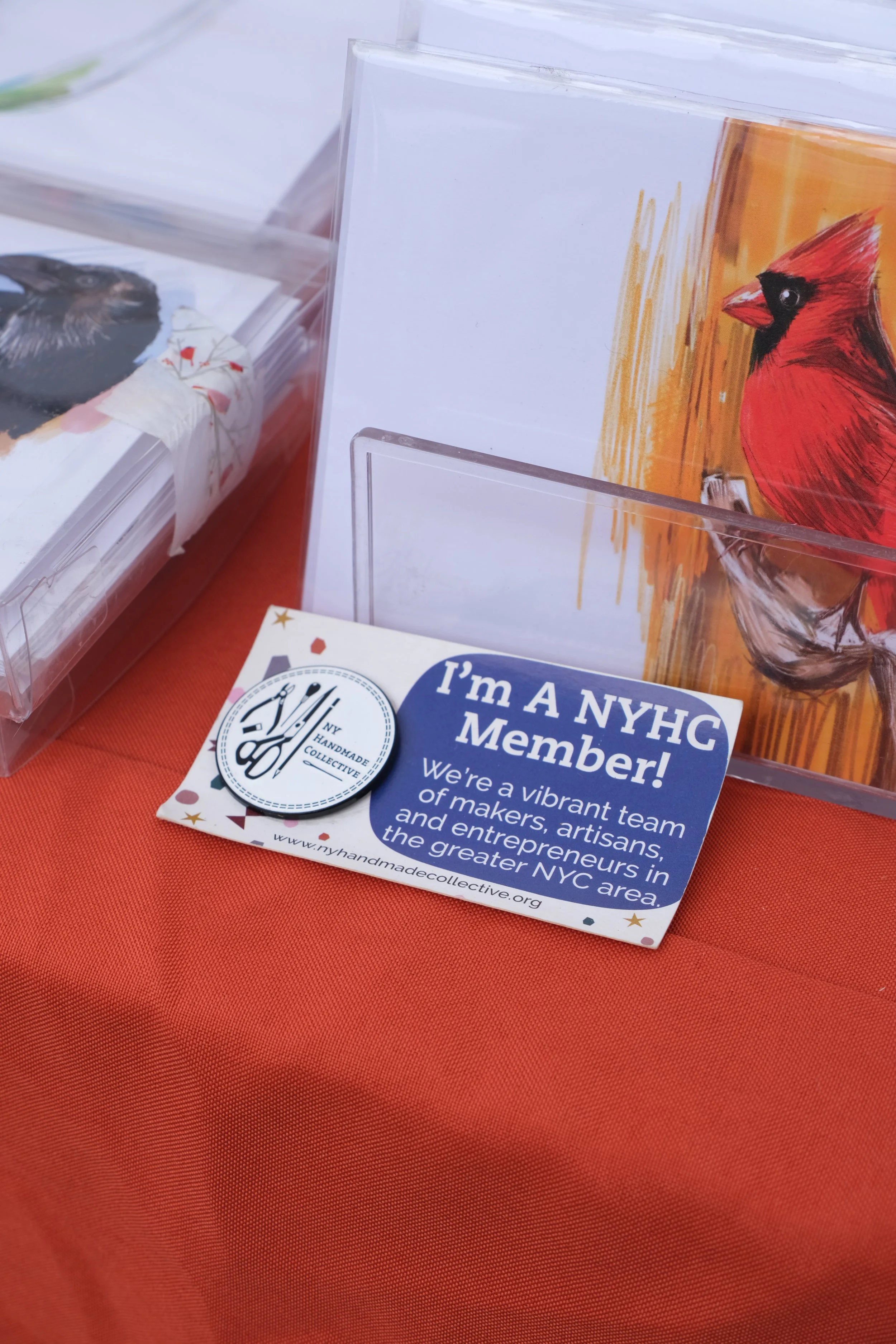

NY Handmade Collective

"Mother's Day",

"Wardrobe Refashion",

"clothes",

"handmade",

"mom",

"wedding dress"

NY Handmade Collective

Read More

"clothes",

"clothing",

"denim",

"how-to",

"jeans",

"sewing",

"tutorial"

NY Handmade Collective

"clothes",

"clothing",

"denim",

"how-to",

"jeans",

"sewing",

"tutorial"

NY Handmade Collective

Read More