"DIY",

"air dry clay",

"clay",

"homemade polymer clay",

"how-to",

"polymer clay",

"purty bird",

"sculpting",

"sculpture"

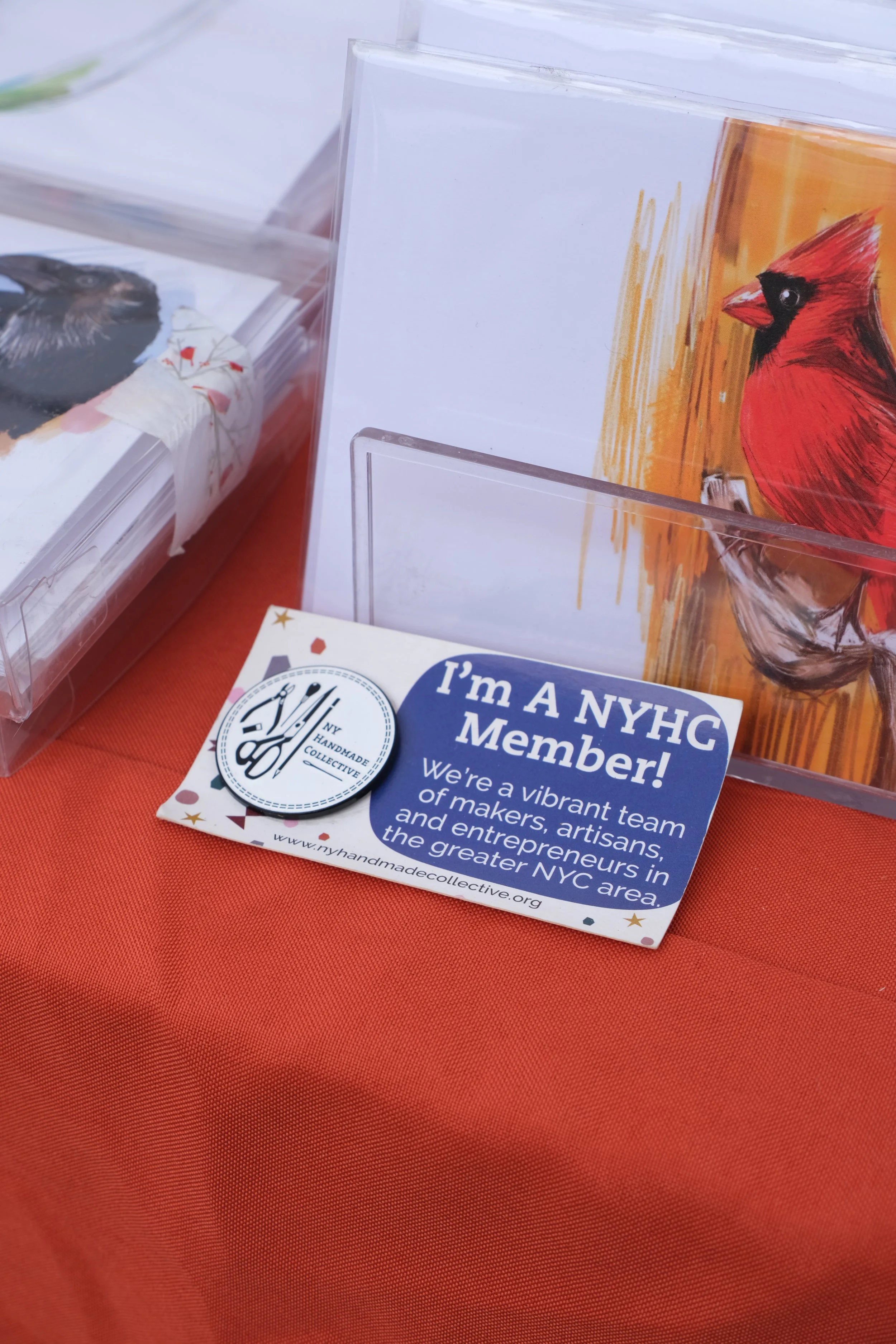

NY Handmade Collective

"DIY",

"air dry clay",

"clay",

"homemade polymer clay",

"how-to",

"polymer clay",

"purty bird",

"sculpting",

"sculpture"

NY Handmade Collective

Read More

"beginner lesson",

"felt",

"how-to",

"purty bird",

"sewing machine",

"sewing"

NY Handmade Collective

"beginner lesson",

"felt",

"how-to",

"purty bird",

"sewing machine",

"sewing"

NY Handmade Collective

Read More

"beginner lesson",

"how-to",

"purty bird",

"sewing machine",

"sewing",

"tutorial"

NY Handmade Collective

"beginner lesson",

"how-to",

"purty bird",

"sewing machine",

"sewing",

"tutorial"

NY Handmade Collective

Read More

"beginner lesson",

"egghead",

"how-to",

"machine",

"purty bird",

"sewing",

"step-by-step guide",

"tools",

"tutorial"

NY Handmade Collective

"beginner lesson",

"egghead",

"how-to",

"machine",

"purty bird",

"sewing",

"step-by-step guide",

"tools",

"tutorial"

NY Handmade Collective

Read More

"beginner lesson",

"how-to",

"learn to sew",

"sewing machine",

"tools",

"tutorial"

NY Handmade Collective

"beginner lesson",

"how-to",

"learn to sew",

"sewing machine",

"tools",

"tutorial"

NY Handmade Collective

Read More